General Advantage

Detailed Description

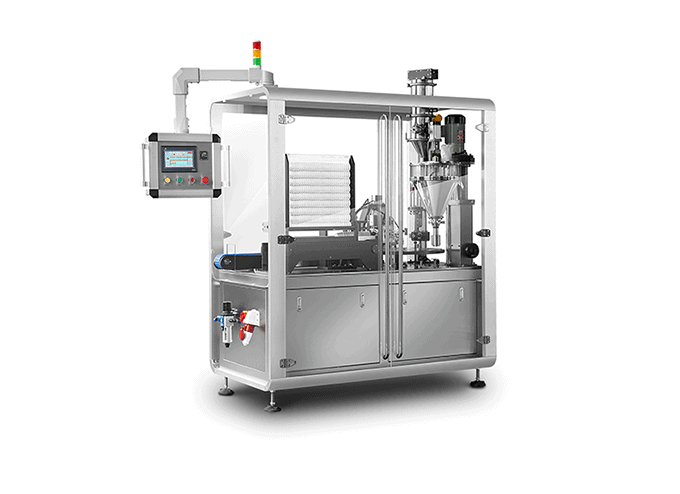

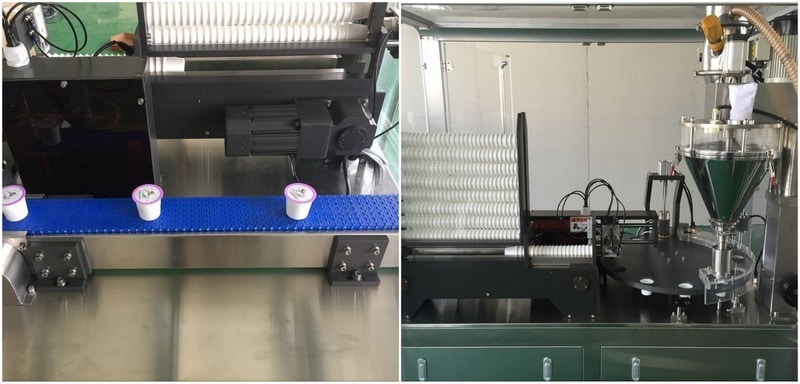

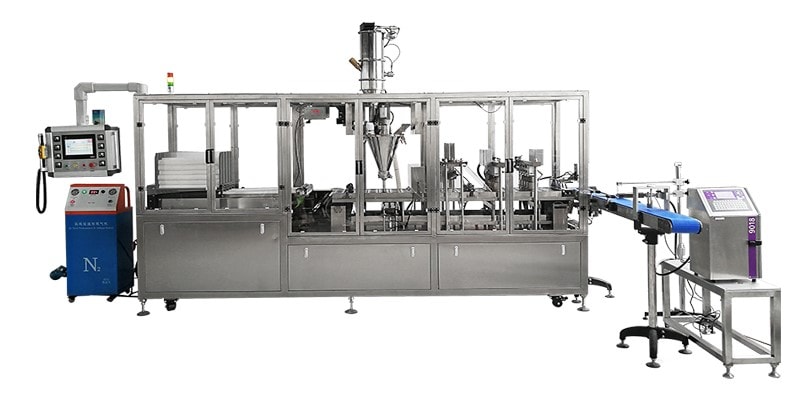

This machine is applicable for various types of capsules filling and sealing.

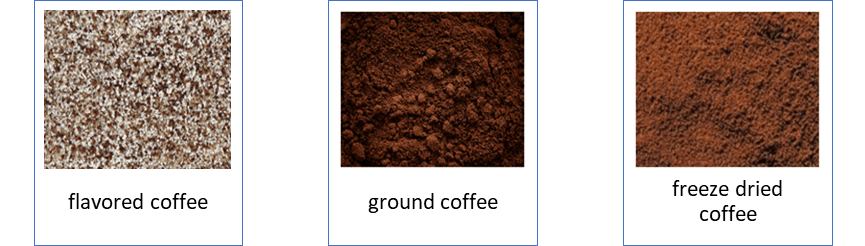

Configured with dosing device- auger screw, applicable to pack various coffee products, such as flavored coffee, ground coffee and freeze dried coffee, etc.

Capsules Formats

Upon the buyer’s request, able to customize the machine to adapt different shaped capsule cups, such as:

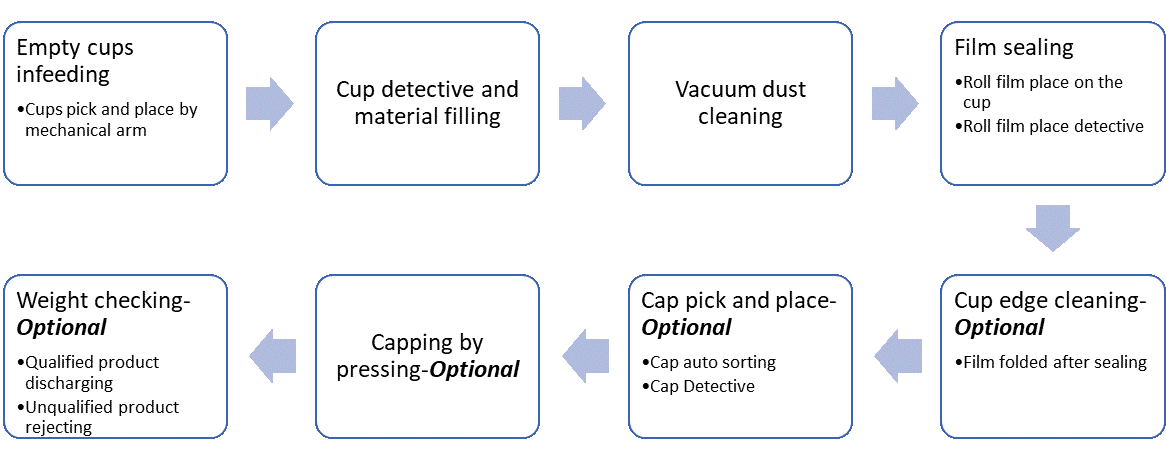

Working Process

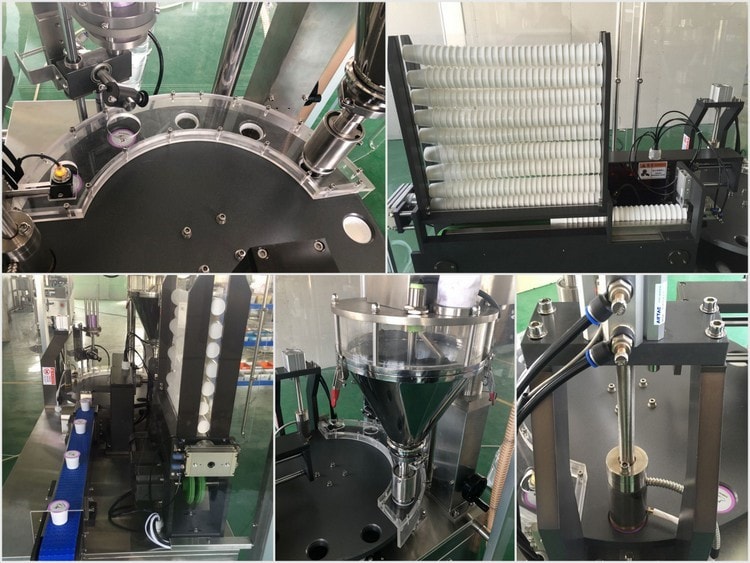

Standard Features

- High strength aluminum frame constructed protection shield

- Stainless Steel 304 configuration for product touching part and other main parts

- High strength anodized aluminum rotating plate

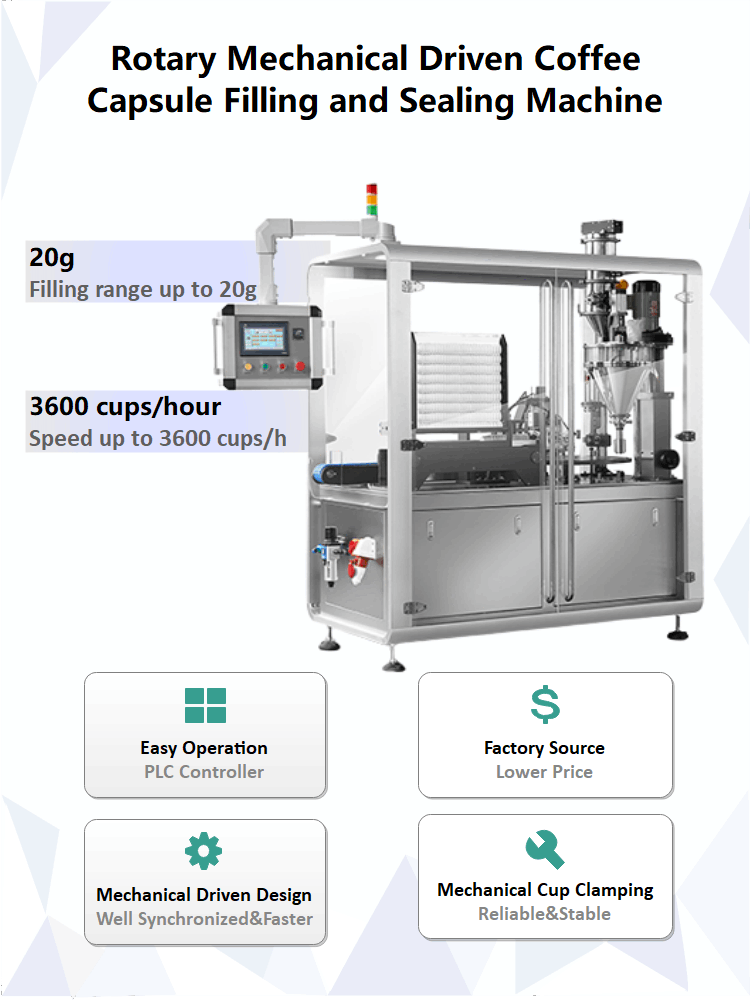

- Mechanical driven design, less pneumatic components, more reliable, well synchronized and faster

- Frequency converting motorized indexing device for main driven

- PLC and Touch screen HMI control

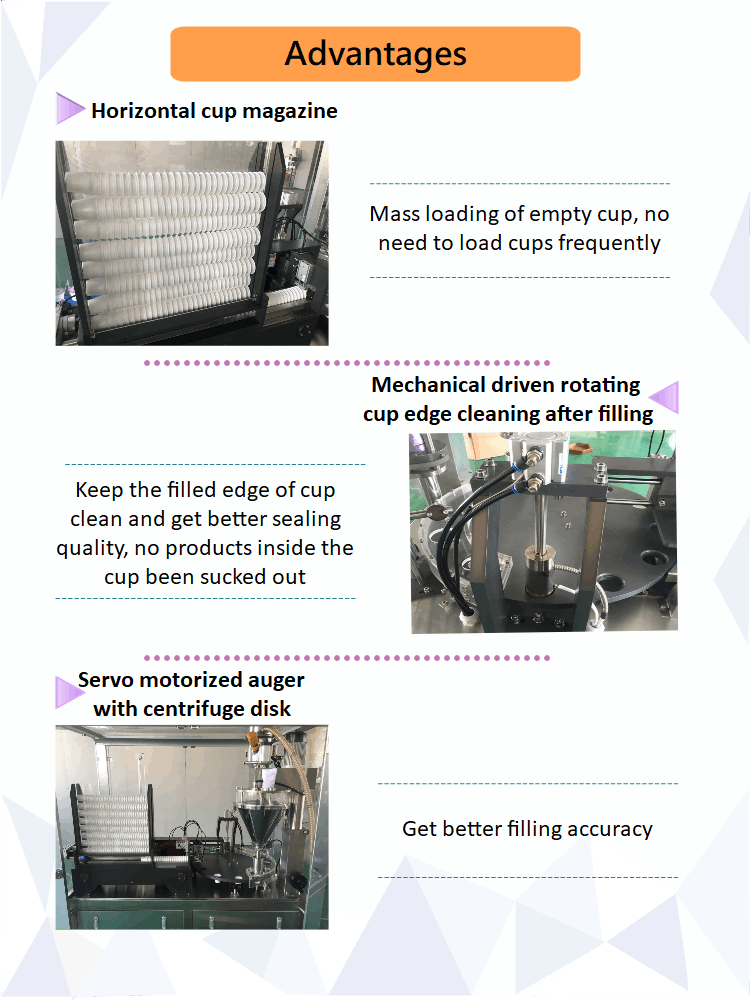

- Horizontal cup magazine for empty cup mass loading

- Mechanical cup clamping instead of vacuum sucking

- High precise sever motorized auger and volume adjustable by PLC

- Mechanical lid sucking and positioning

- Mechanical driven rotating cup edge cleaning after filling

- Self-adapting sealing device to get better sealing quality

- No cup no fill and seal, No lid no seal, door open machine stop interlocks

- Discharge conveyor for sorting, bagging or boxing

Optional Features

- Mass cup unscrambling and sorting device

- Nitrogen flushing with transparent gassing chamber

- Other type of cup fill and seal, like K-cup, Dolce Gusto

- Sever motorized Lid punching from film roll and/or logo embossing

- Vacuum loading device

Advantages

Practically, compare with the other type of cup fill seal machine, the advantages as indicated as following:

| No | Gloex Product | Others | Advantages |

| 1 | Mechanical driven design | Pneumatic driven design | Reliable, well synchronized and faster |

| 2 | Mass loading of empty cup | Limit loading of empty cup | No need to load cups frequently |

| 3 | Self-adapting sealing device | Sealing device with spring only | Get better sealing quality |

| 4 | Mechanical driven rotating cup edge cleaning after filling | Simple sucking by vacuum tube | Keep the filled edge of cup clean and get better sealing quality, No products inside the cup been sucked out |

| 5 | Servo motorized auger with centrifuge disk | Stepper motorized auger | Get better filling accuracy |

| 6 | Discharge conveyor | Discharge chute | Convenient for downstream sorting, bagging or boxing |

Technical Specification

| Catalogue/4M | R1 |

| Filling Heads | 1 |

| Filling Range | 0-20 gram, adjustable |

| Filling Accuracy | <=+/-0.05g |

| Filling Speed (cups/hour) | 2700-3600 |

| Power Requirement | AC 380/220V 50Hz |

| Power Consumption (KW) | 1.5 |

| Compress Air Required (Mpa) | 0.6-0.8 |

| Compress Air Consumption (m3/min) | 0.1 |

| Approximate Weight (kg) | 850 |

| Dimension (mm) | 1600*900*2000 |

Contact Us to Know More Models of Coffee Capsule Packing Machine!

System Overview