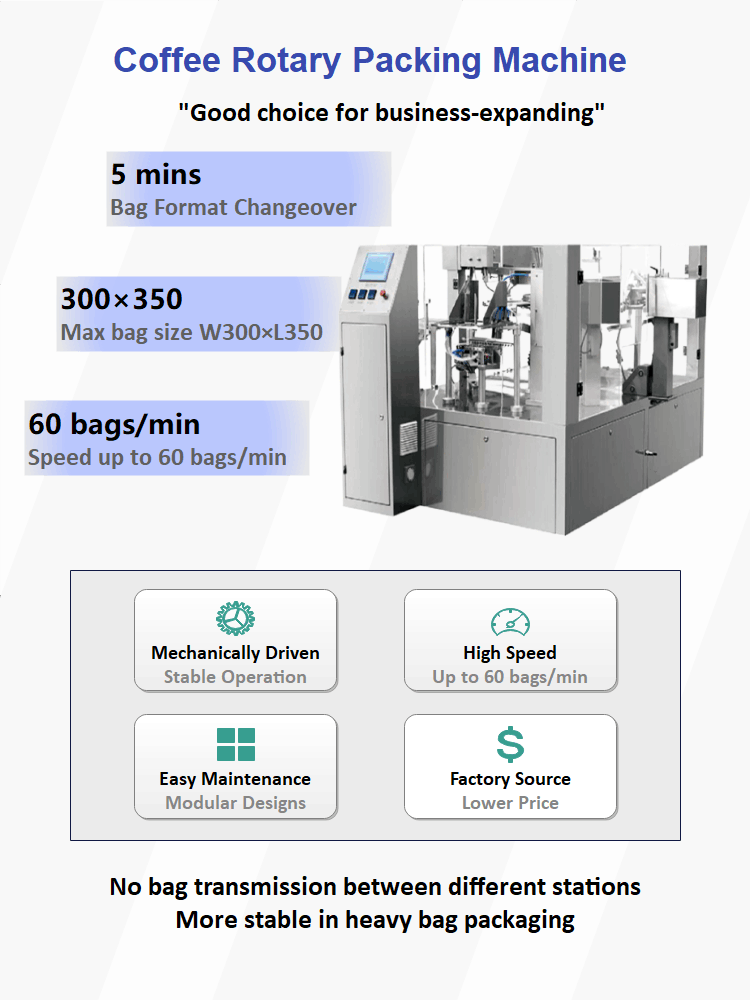

General Advantage

Detailed Description

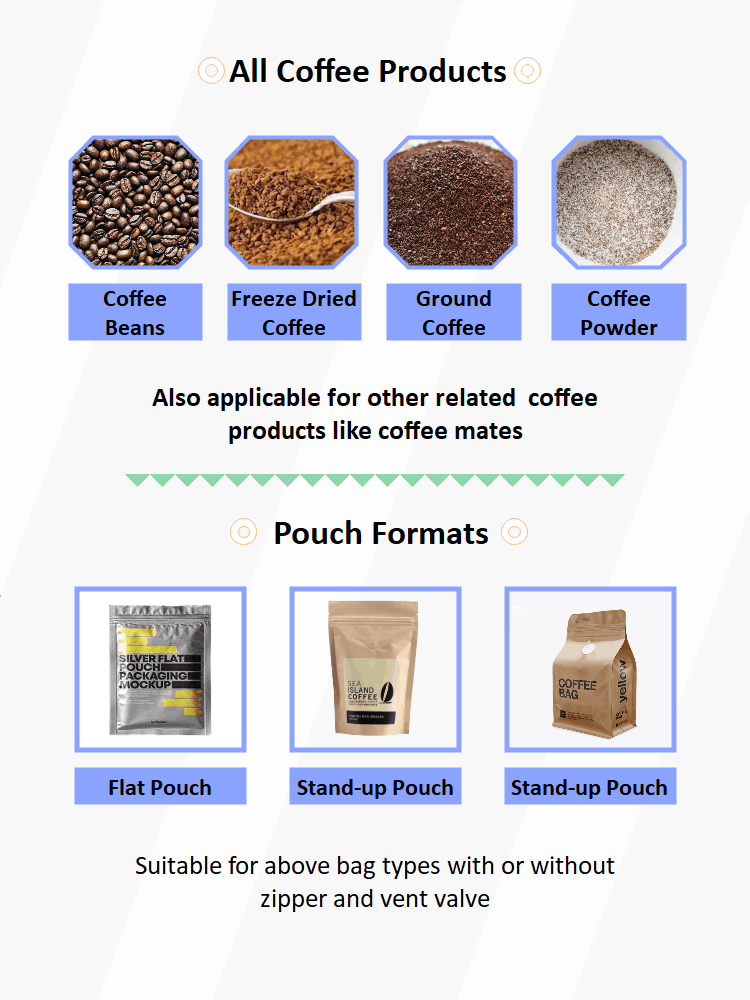

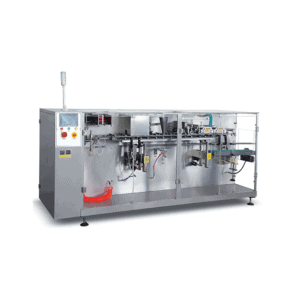

This machine is applicable for various coffee products, like coffee bean, ground coffee, freeze dried coffee, filling, sealing and packing with premade pouch.

Pouch Formats

This machine applies to premade pouch with laminate heat sealable material, such as Kraft paper, OPP/PE, BOPP/OPP/PE, PET/AL/PE etc.

Configuring different accessories, it applies to various design pouches like flat pouch, stand up pouch, with or without zipper or vent valve.

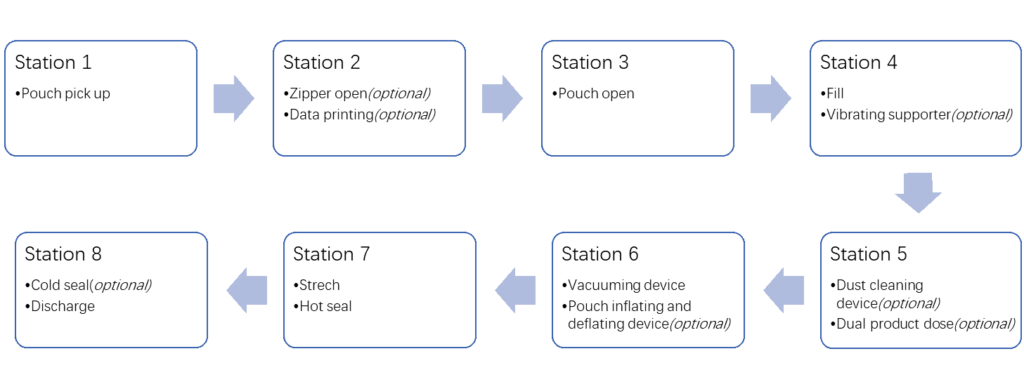

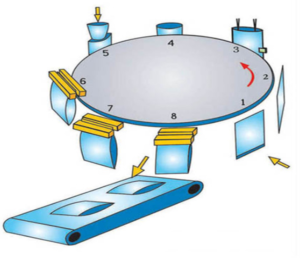

Working Processes

The main working processes include: pouch pick up, pouch open, product fill, hot seal and discharge. By configuring with different accessories, like zipper opening device, dust cleaning device and vacuuming device, capable to fill with different types of pouch, or achieve different process requirements.

Followings are the typical working processes diagram:

Standard Features:

- 8 or 10-station design to meet complex packaging process requirements

- Configured with different dosing devices, capable to pack coffee bean, ground coffee, freeze dried coffee

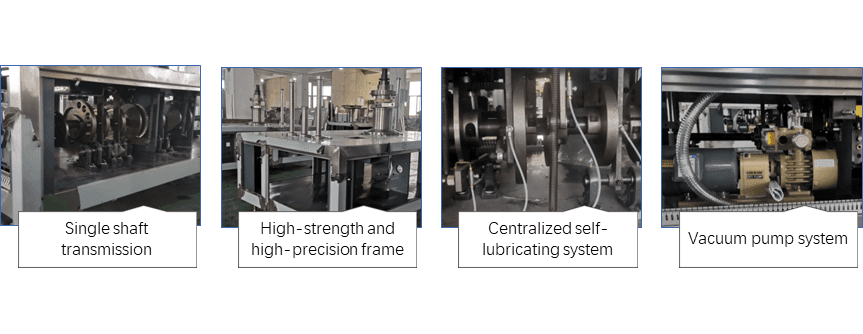

- Single shaft transmission, accurate operation, high reliability, easy maintenance

- PLC touch screen control, easy to operation, easy for troubleshooting

- PID temperature control system for reliable sealing effect

- Multi-mechanical transmission station, accurate stroke, reliable operation

- Synchronous bag width adjustment device, 1 rotating wheel adjustment controls all stations to fit with new bag width

- Centralized self-lubricating system, with small lubricating oil tanks and distribution pipes, easy maintenance

- High-strength and high-precision frame, higher precision, high-strength cam, more stable operation

- Configured with vacuum pump system for pick up and open bag, reduce the air consumption of the whole system, energy saving and noise reduction

- No bag opening, no filling and sealing

- No filling, no sealing

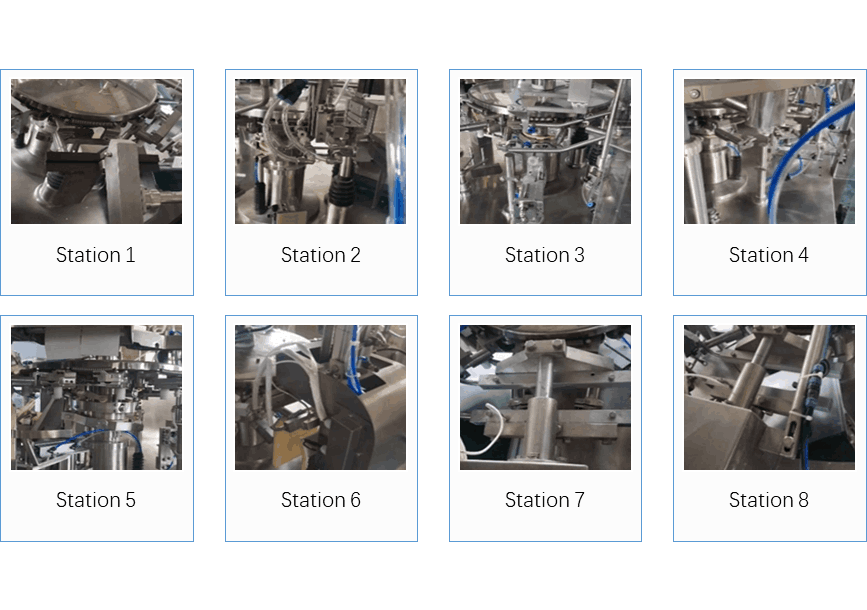

Optional Features

In order for adapting different requirements, the customized products can be supplied with the optional features as following.

| No | Feature | Description | |

| 1 | Zipper Opening Device | 1) The clamps are arranged in front and back position to apply for small bag width, minimum to 100 mm

2) Mechanical driven zipper opening device moves up and down, high reliability |

|

| 2 | Horizontal Pouch Loading Device | 1) Increase bags quantity in the bag magazine

2) Zipper bag loading more reliable |

|

| 3 | Date Printing Device | Ribbon Coding Device / Inkjet printer / Laser Printer | |

| 4 | Dust Remover on the Seal Area | Motorized dust remover to make the sealing area clean before sealing | |

| 5 | Vibrating Bracket | 1) Support the heavy product

2) Compact the loose product 3) On/Off adjustable |

|

| 6 | Poking Device | 1) Poking the product from the sealing area and not affect the sealing process

2) Pneumatic/Mechanical driven for option |

|

| 7 | Auto Lubrication System | 1) Auto lubricate some mechanical driven parts, like cams

2) Include the lubricating pipes and oil tank |

|

| 8 | Pouch Deflating Device | 1) Apply for air deflating before sealing

2) Air driven out by 2 pneumatic driven sponge pieces |

|

| 9 | Pouch Bottom Opening Device | 1) Apply for stand up or side gusset pouch (top side welded)

2) Pneumatic driven |

|

| 10 | Guide Rail | 1) Apply for Bag Supporting Tray Device big heavy bags packing

2) Reduce the centrifugal force during pouch running, to prevent the bags breakaway from the clips |

|

| 11 | Bag Supporting Tray Device | 1) Continuously support the bags during running

2) Trays configuration quantity subject to the working stations 3) Typically for big heavy bags supporting |

|

| 12 | Water Washable Application | 1) Cleaning water drainage groove, and

2) Reinforce the seals for the components go through the base |

|

Technical Specification

| Type/1K-xxxxx | 8-200 | 8-250 | 8-300 |

| Process Stations | 8 | 8 | 8 |

| Pouch Size-Length(mm) | 100-350 | 100-350 | 100-350 |

| Pouch Size-Width(mm) | 70-200 | 110-250 | 180-300 |

| Packing Speed (pouches/min) | 20-60 | 20-60 | 20-60 |

| Power Requirement(V/Hz) | 380VAC 3P+N+E 50HZ | 380VAC 3P+N+E 50HZ | 380VAC 3P+N+E 50HZ |

| Power Supply(kW) | 3.0 | 3.0 | 4.0 |

| Compress Air Required(Mpa) | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Compress Air Consumption(m3/min) | 0.3 | 0.3 | 0.3 |

| Approximate Weight(kg) | 1500 | 1500 | 1800 |

| Dimension(mm) | 2160*1600*1500 | 2160*1600*1500 | 2420*1820*1500 |

Related Machines

| Ground Coffee | Freeze Dried Coffee | Coffee Bean | |

| Material Dosing Device | |||

| Multi Heads Weigher | √ | √ | |

| Linear Weigher | √ | √ | |

| Auger Screw | √ | ||

| Materiel Feeding Device |

|||

| Screw Loading Machine | √ | ||

| Z-shape Bucket Elevator | √ | √ | |

| Vacuum Loading Machine | √ | √ | √ |